- Proper Tensioning Ensure the belt is correctly tensioned, as both over-tightening and slackness can lead to premature wear or failure.

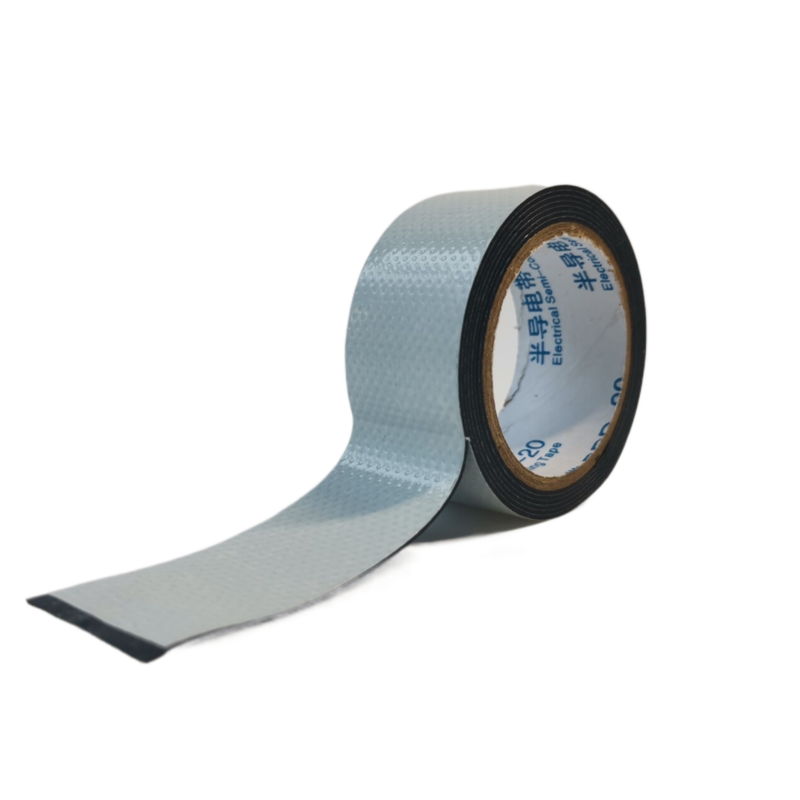

What is electrical taped used for? Electrical tape has many uses and is categorized into four different varieties. Read on to discover what differentiates rubber, vinyl, mastic, and varnished cambric.

In an era where safety and efficiency are paramount, especially in industrial applications, fireproof gasket tape has emerged as a critical component for ensuring both these aspects. This specially designed adhesive tape is engineered to withstand high temperatures and mitigate fire risks, making it an invaluable asset in various sectors such as manufacturing, automotive, aerospace, and construction.

Mastic is a very tacky material with extreme elongation properties. Rubber mastic tape combines an ethylene propylene rubber backing with a conformable mastic layer.Rubber Mastic Tape 2228 integrates some of the best qualities of both materials−higher temperature rating, conformability, dielectric strength. It’s one tape that belongs in every toolkit.

yellow and black floor tape. For example, it can be used to section off different areas within a warehouse or storage facility, making it easier to locate and manage inventory. It can also be used to create pathways or designated work areas, improving efficiency and productivity.

yellow and black floor tape. For example, it can be used to section off different areas within a warehouse or storage facility, making it easier to locate and manage inventory. It can also be used to create pathways or designated work areas, improving efficiency and productivity.Creative Applications

2. Cut to length.It is important to have the tape at the correct length before applying it. Once it adheres. it will be difficult to remove.

2. Superior Adhesion Butyl rubber features high adhesive properties that allow it to bond effectively to various surfaces, including wood, metal, and plastic. This characteristic ensures a tight seal against drafts, moisture, and dust, enhancing the overall energy efficiency of your space.

- Home Improvement and DIY Projects For general repairs, home electrical systems, and protecting outdoor wiring.

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.

butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.In conclusion, butyl weather stripping is a valuable investment for homeowners looking to enhance their property’s energy efficiency, comfort, and durability. Its numerous advantages make it an ideal choice for various applications, preventing energy loss and external disturbances. By properly installing butyl weather stripping, homeowners can ensure a comfortable living environment while also contributing to energy conservation efforts.

2. Manufacturing Facilities In manufacturing, adhering to safety standards is vital. Red and white flooring tape can indicate hazardous zones, highlight equipment locations, or provide guidance for the flow of materials and personnel, helping to streamline operations.

4. Seal the ends When you reach the end of the surface, make sure to press down firmly to seal the ends of the tape. This will prevent any water or moisture from seeping underneath the tape.

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.